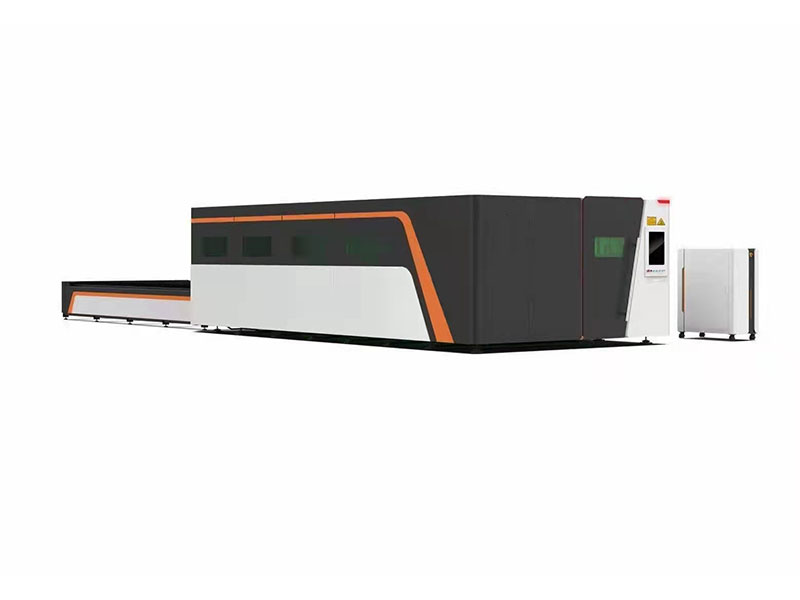

Pipe&Plate due-use Fiber Laser Cutting Machine

Pipe&Plate due-use Fiber Laser Cutting Machine

- Brand: STARRY

- Model: STARRY-3015AT

- Type: Pipe&Plate due-use Fiber Laser Cutting Machine

-

Rating:

- Unit Price: $1900-$2300

- Supply Ability: 700 Sets / Month in Stock

- Delivery: 7-20 Working Days

- Payment Method: T/T, L/C,Credit Cards, e-Checking

- Package: Strong Wooden Package

Products Detail of Pipe&Plate due-use Fiber Laser Cutting Machine

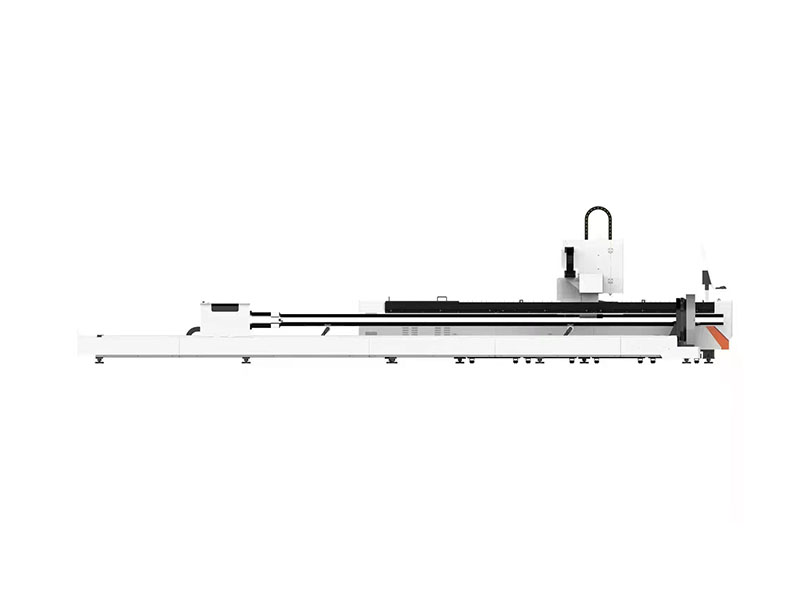

Automatic clamping, efficient and labor- saving, strong support force, clamping deformation, to ensure the accuracy of pipe processing .

Parameters of Pipe&Plate due-use Fiber Laser Cutting Machine

| Model | STARRY-3015AT |

| Laser Source Options | Raycus,Max&IPG |

| Fiber Power Options | 1000W-20000W |

| Laser Wavelength | 1064nm |

| Metal Sheet&Tube Size | 3000*1500mm/6m |

| Control System | Cypcut 3000S |

| Laser Cutting Head | Raytools/Au3tech |

| Application | Carbon steel,stainless steel/Aluminum/Brass/Copper |

| Auxiliary gas | O₂ N₂ |

| Power Supply | 380V, 50HZ/60HZ |

| Application Tube | Round tube,square tube |

| Chuck | Penumatic chuck |

Features of Pipe&Plate due-use Fiber Laser Cutting Machine

Laser Source

Raycus,Max&IPG laser source,100,000 hours long lifetime, 1000W,1500W,2000K,3000W,4000W,6000W,8000W,12000W,20000W for option

Laser Cutting Head

Autofocus laser cutting head can focuse lens through a linear mechanism to change position automatically.Customers can set the program to achieve continuous focus that completing the rapid piercing and cutting material with different thickness

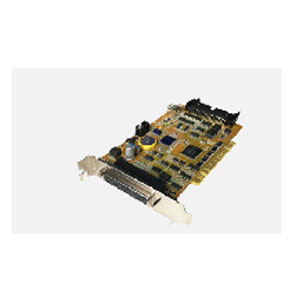

Cypcut Control Board

FSCUT2000 laser cutting system is a full-solution open-loop control system specially designed for sheet metal fabricaton industry, with features of easy to install and adjust, excellent performance and fully integrated solutions.

Servo Motor

High speed, high precision, high reliability, high power; Gantry double drive mechanism has high damping coefficient, good rigidity, could withstand high speed and high acceleration

Heavy Duty Machine Bed

Aggravated and reinforced integrated bed with hot processing, to support the gantry moving high speed, and accuracy support 0.02mm.

Gear Rack

high precision,long life,Can provide rigorous support for quenching helical gears and grinding helical gears, so that the load drive structure is compact, can effectively reduce the driving torque.

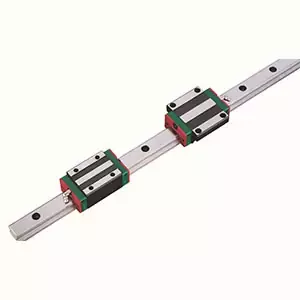

Linear Guide

Each guide rail performs strict photoelectric self-collimation tests, make sure the accuracy is within 0.03mm.

Reducer

More stable and cost-efficient Free maintenance High precision of gear meshing; Low noise.

The Third Generation Aviation Aluminum Gantry

It is manufactured with aerospace standards and formed by 4300 tons press extrusion molding. After aging treatment, its strength can reach 6061 T6 which is the strongest strength of all gantries. Aviation aluminum has many advantages, such as good toughness, light weight, corrosion resistance, anti-oxidation, low density, and greatly increase the processing speed.

low-pressure steel film casting process

Using low-pressure steel film casting process, the beam has high compactness, the surface quality of the beam is smooth, and the integrity and rigidity are excellent.At the same time, it has good toughness, ductility and corrosion resistance. Reduce the load of the servo motor, reduce the inertia,While saving electricity costs, it improves the operating speed of the equipment

Water Chiller

Real-time display of the current water temperature; Unique dual water path design, one for laser source cooling, another for cutting head cooling, efficient operation of auxiliary machine; Abnormal temperature alarm

Strong and stable body

Machine body need to through large portal milling machine, it can make sure the machine precision. Our all machine body use rectangular tube welded bed, stable and strong. Machine body stable, then when machine fast speed operation is also stable, the cutting effect will be better. After long time using, the machine body well, it can not not easy to out of shape, even use more than 20 years

Qick Wear Parts of Pipe&Plate due-use Fiber Laser Cutting Machine

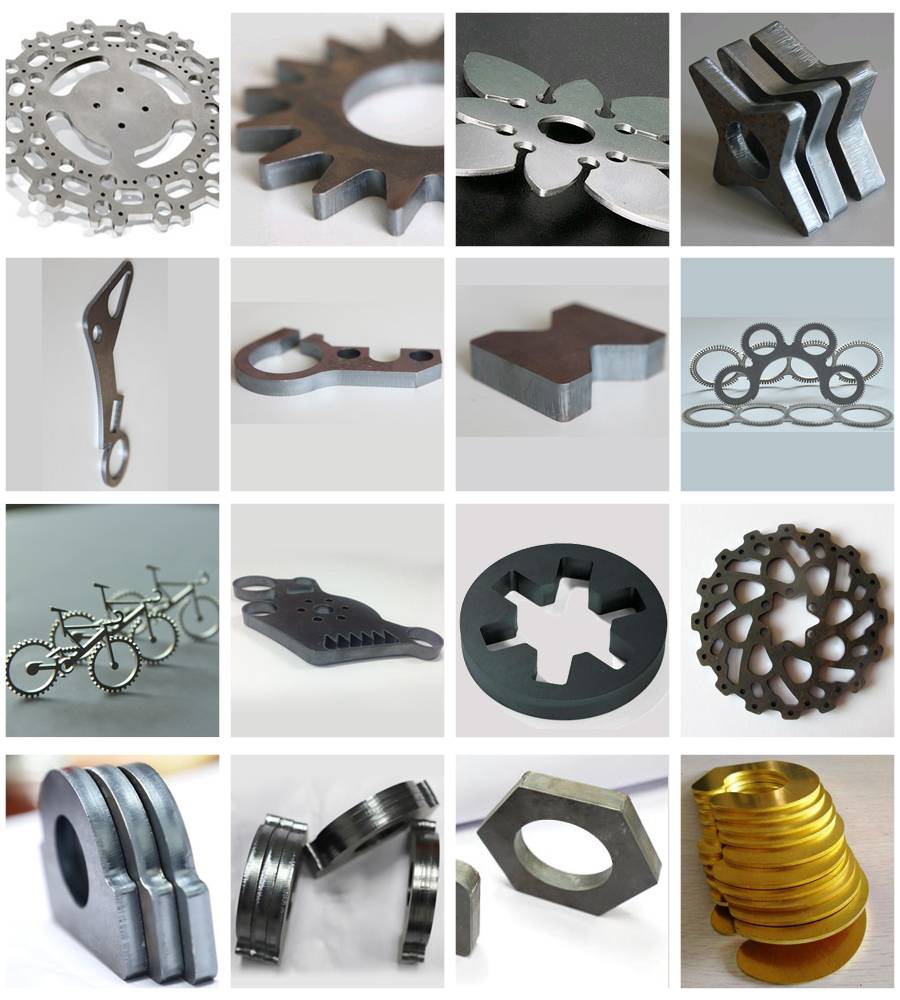

Applications of Pipe&Plate due-use Fiber Laser Cutting Machine

Pipes Professionally cutting square pipes, round pipes, rectangle pipes, D-shaped pipes and hexagon pipes and etc .

Packing Shipping of Pipe&Plate due-use Fiber Laser Cutting Machine

- The innermost layer is EPE pearl cotton film package.

- The middle layer is wrapping up with environmental protection material.

- And the outermost layer is winding up with PE stretch film.

- Strong water resit bottom in plywood.

- Plywood packing and steel strip outside fixed the box.

- Finishing packing by normal container or frame container.

FAQs of Pipe&Plate due-use Fiber Laser Cutting Machine

We are manufacturer in China since 2008.

Usually it is 3-5 days after reveing you payment.If your order quantity is big,it will take 5-10 days.The delivery time depends on the order quantity.

Payment less than 5000USD, 100% T/T in advance. Payment more than 10000USD, 30% T/T in advance ,70% balance before shipment.

Yes. We can print your Logo on both the products and the packages

- Strict detection during production.

- Strict debugging on products before shipment and intact product packaging ensured.