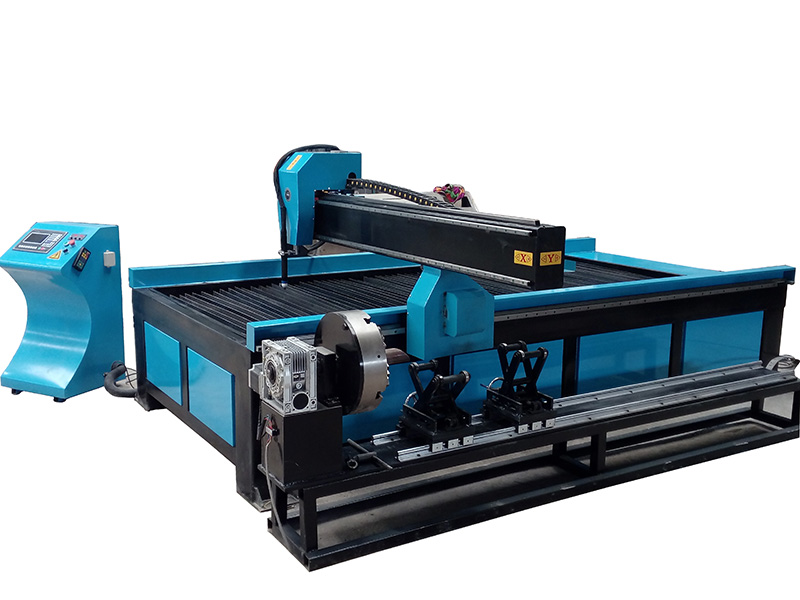

CNC Plasma Cutter

CNC Plasma Cutter

- Brand: STARRY

- Model: QT-P3015

- Type: CNC Plasma Cutter

-

Rating:

- Unit Price: $1900-$2300

- Supply Ability: 700 Sets / Month in Stock

- Delivery: 7-20 Working Days

- Payment Method: T/T, L/C,Credit Cards, e-Checking

- Package: Strong Wooden Package

Products Detail of CNC Plasma Cutter

plasma cutting machine can cut various metals that are difficult to cut by oxygen cutting with different working gases, especially for non-ferrous metals (aluminum, copper, titanium, nickel), the cutting effect is better; its main advantage is when cutting metals with small thicknesses , The plasma cutting speed is fast, especially when cutting ordinary carbon steel sheets, the speed can reach 5 to 6 times that of the oxygen cutting method, the cutting surface is smooth, the thermal deformation is small, and there is almost no heat affected zone.

Parameters of CNC Plasma Cutter

| Model | QT-P3015 |

| Plasma Power | 45A,63A,100A,120A,160A,200A,300A,400A |

| Control System | STARFIRE |

| Software | Starcam |

| Torch height control | Automatic |

| Machine Body | Heavy duty machine body |

| Servo motor | Leadshine |

| Reposition precision | 0.02mm |

| Processing precision | 0.1mm |

| Power Supply | 380V, 50HZ/60HZ |

| Packing Dimensions | 2280*3850*1850mm |

| Gross Weight | 1800kgs |

Our Advantage of CNC Plasma Cutter

- We do this line many years, have rich experience and professional knowledge, will let you get the most suitable machine with the right configuration. This ability can let you avoid many mistake and avoid some trouble. Other factory usually lack this experience, and bring some trouble for the real customer.

- If use the plasma cutting machine to cut the the thick meal, have to use the arc height adjust system, while our height adjust system use the high sensor, one minute can send out 12,000 signal per minute, while other height adjust system usually send out 10000 signal per minute, so our cutting quality more better than other factory and cutting speed a litter faster than the same power plasma source.

- we equipped the two fan for take the cutting smoke out from the room, front fan will blow to back, the back fan will exhaust the smoke out from the machine and out from the room. This way, will efficiency to let the workshop in the good environment. While other factory does not have this fan or only have one.

- All our machines have to be checked three times, then allow to send out ,and finally will put one 8GB flash disk into the package, when the customer received the machine, can easy check the video from the 8GB flash disk ,then do the easy operation, in the video nearly like hand by hand do the teaching job, so can let the customer in the shot time to let the machine create the profit. While we also have the video platform, after you purchase the machine, we will give you one password, then you can easy to get the efficiency “after-sell service” from the internet. While other small factory usually, only check one time for the machine, and no 8GB flash disk, and no video platform, then it is hard for you to get the good after-sell service.

- The painting: all our machine body have been processed by professional anti-rust treatment. First, we spray 2 times anti-rust paint to ensure that all parts of the machine in a fully protected state, and then spray color. This can effectively prevent the machine rust, resulting in damage to the machine. Other manufacturers do not take anti-rust treatment or only spay 1 time rust paint.

- Just because our machine all equipped the professional parts, and test more seriously for the whole machine, so our guarantee period it is 2 years, while other factory it is only 1 years.

- we will free provide 2G processing design (USD 320) and Australia professional metal cutting software for you, in the 2G processing design have thousand beautiful graphic, after you get the machine, you can let the machine do a lot of beautiful work, while no need find the engineer to help you to design.

- Machine structure is designed by famous mechanical professor, to add many columns for each bean. So that the machine body can bear more weight for large, thick metal sheets without deforming. But some small factories will not add these parts for saving cost, their machine is easy to deform for thick metal

Applications of CNC Plasma Cutter

Packing Shipping of CNC Plasma Cutter

- The innermost layer is EPE pearl cotton film package.

- The middle layer is wrapping up with environmental protection material.

- And the outermost layer is winding up with PE stretch film.

- Strong water resit bottom in plywood.

- Plywood packing and steel strip outside fixed the box.

- Finishing packing by normal container or frame container.

FAQs of CNC Plasma Cutter

We are manufacturer in China since 2008.

Usually it is 3-5 days after reveing you payment.If your order quantity is big,it will take 5-10 days.The delivery time depends on the order quantity.

Payment less than 5000USD, 100% T/T in advance. Payment more than 10000USD, 30% T/T in advance ,70% balance before shipment.

Yes. We can print your Logo on both the products and the packages

- Strict detection during production.

- Strict debugging on products before shipment and intact product packaging ensured.